5 Reasons Why Flexible Packaging is Better

Traditionally, packaging for semi-liquid and liquid products is manufactured in a rigid form. While rigid packaging certainly does the job well, it comes with several drawbacks. Rigid packaging tends to be heavy, expensive to produce, and takes up a lot of space.

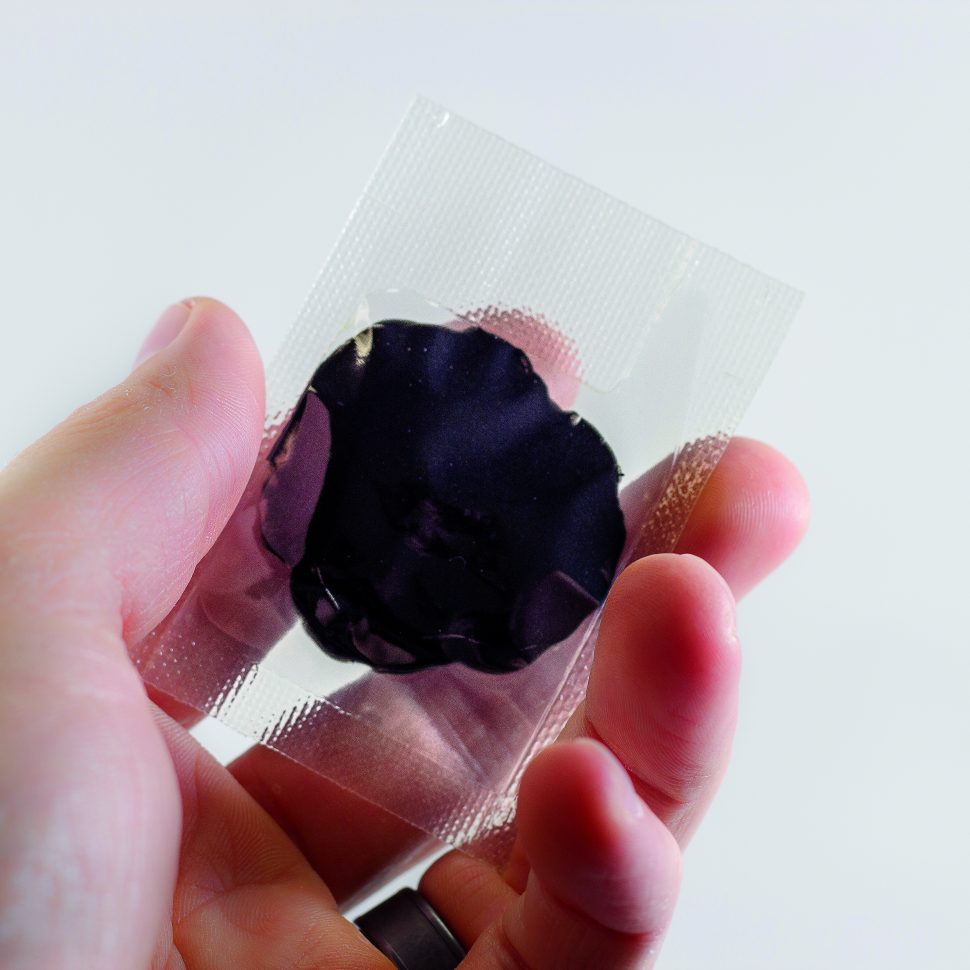

Flexible packaging is rapidly taking over as the preferred method to contain liquid and semi-liquid products. Many businesses realize the massive money-saving potential, convenience, and other benefits of switching to a flexible packaging solution. Here are five great reasons why you should convert to using flexible packaging.

One: Reduce Costs

Creating a bag or pouch requires less material than rigid counterparts. Using fewer materials means less cost may be incurred in the manufacturing process. Ultimately, these costs are passed to the consumer making your product more affordable.

Two: Ease of Transportation

Flexible packaging for semi-liquid products weighs far less than rigid packaging but is just as durable and strong. Therefore, transporting it is not a problem. In fact, flexible packaging weighs less and takes up less room. This means you can transport more of your product at a cheaper price.

Three: More Sustainable

It takes fewer materials to manufacture flexible packaging for liquid products. Fewer materials mean less waste going to landfills. Additionally, the manufacturing process requires fewer fossil fuels and less water to create flexible packaging than rigid varieties.

Four: Extended Life of Products

Flexible packaging for semi-liquid products and liquid products can be UV resistant, better protecting its contents. The protection is further extended by the resealing properties of the pouches. Additionally, the plastic film used in the packaging does a better job than rigid packaging at keeping contaminants out and allowing resealing.

Five: Store More

Flexible packaging for liquid products is convenient and compact. In the space needed to store 30 plastic bottles, you can store 840 plastic pouches with spouts. One truck full of flexible packaging is equal to 15-25 trucks full of rigid packaging. That makes a big difference to your storage requirements, as well as you shipping costs. (Source: FTA)

Flexible packaging is the fastest-growing area within the packaging industry. It’s easy to see why. Its numerous benefits save you time, space, and money. Make the switch; you won’t regret it. Liquipak provides flexible packaging solutions to meet the exact needs of many industries. These markets include detergent, pharmaceutical, dental, cosmetics, first aid, and automotive aftermarket flexible packaging. Please contact us to learn more about how we can help your business produce a flexible package that will meet your exact requirements.